From the lab to the store

HZB researchers are supplying smartwatches with solar energy

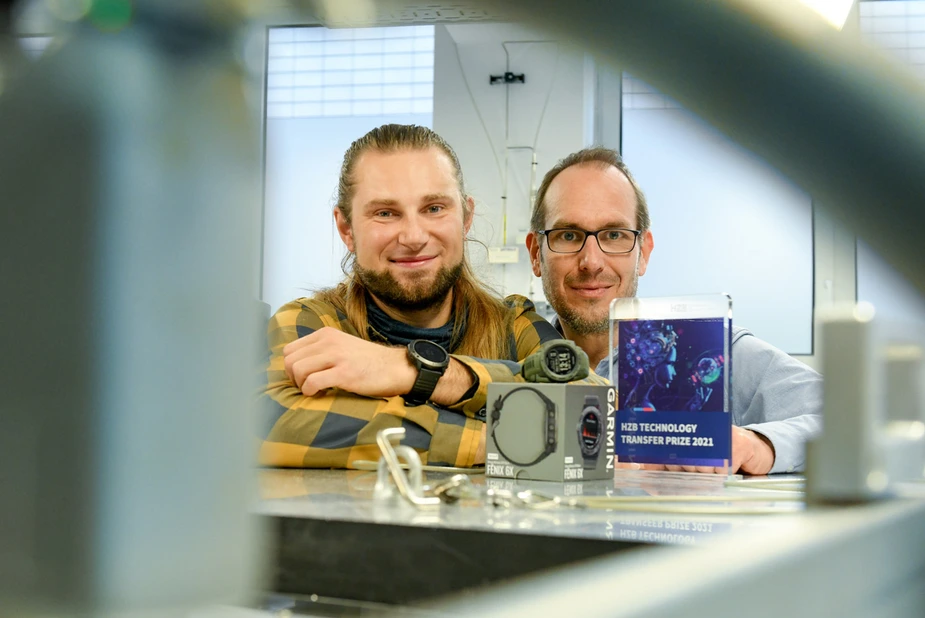

Ideally, the winners of the HZB Technology Transfer Prize go down the road of transforming a research question into a product and integrating it into our lives. The team surrounding Tobias Henschel and Bernd Stannowski followed this path and won more than just a prize.

“Smartphones, smartwatches, tablets—we carry around a lot of electronic devices around with us and they all need electricity,” says Tobias Henschel. “We seek to provide consumer electronics with energy from sunlight using transparent solar cells.” For nine years now, Tobias Henschel as been working at HZB, the Helmholtz Centre for Materials and Energy in Berlin. “Currently, my main task is to oversee systems for plasma-supported gas phase synthesis,” he says. They are used to put ultra-thin sheets of amorphous silicone on a supporting material. “Today, these are wafers of crystalline silicone,” he says, “before they were sometimes made of glass. I was already working together quite closely with Bernd Stannowski while were doing that research, which is how I got involved with the project.”

This was in 2015. “The French company Sunpartner Technologies approached us,” Bernd Stannowski remembers. “They wanted us to conduct a few experiments to deposit silicone layers on glass plates. Initially, we didn’t actually know what it was we were working on. It took a few months until this was cleared up.” The physicist was there from the beginning. His field of expertise: Thin-film silicone. This is what he wrote his PhD about. This is what he worked on for eight years in the photovoltaics industry. A blessing for the new project. “A lot of the questions I could answer purely from experience.” After taking on individual orders from Sunpartner Technologies for about a year, the two companies began to cooperate. “It was only then that we fully realised what the big picture was.”

The “big picture” was no less than building solar cells into the glass of smartwatch displays, invisible to the human eye. “Sunpartner had developed a special procedure for this,” explains Stannowski. “Using photolithography, we etch tiny areas into the solar cells.” Simply put, they are filled with holes. “We create something like a sieve,” Henschel adds. “The breadth of the individual solar cell units is currently about ten micrometres.” The first product using this technology came to market as early as 2017: the LunaR smartwatch. “The solar cells used in that were built here at the institute,” Tobias Henschel remembers. “It was then a matter of scaling up the technology and going into series production.” Here, too, the HZB team was a key player. “We transferred our process know-how to a factory in Asia,” says Bernd Stannowski. “And when Sunpartner’s consumer electronics division was sold to Garmin Ltd. in early 2019, we did the same in another factory.”

Watches featuring transparent solar cells are now being mass-produced and, on top, a fruitful cooperation has developed between team of HZB, the technology consulting company Novability—an HZB spin-off by former teammate Sebastian Neubert—, and Garmin, an electronics specialist. Through research, development, pilot production, and licensing contracts, the project has generated over 1.3 million euros for HZB. Something that certainly played into their hands at the Technology Transfer Award. “We were quite optimistic because the technology transfer was already very successful,” says Bernd Stannowski. “Of course, the other nominees also had incredibly interesting projects. But the fact that we won in the end was really a great feeling. Not only does it honour the commitment of the entire team but it also creates more visibility for our other projects.”

Kai Dürfeld for Adlershof Journal