Green hydrogen: Why do certain catalysts improve in operation?

HZB Team analysed catalysing mineral materials

Crystalline cobalt arsenide is a catalyst that generates oxygen during electrolytic water splitting in the production of hydrogen. The material is considered to be a model system for an important group of catalysts whose performance increases under certain conditions in the course of electrolysis. Now a HZB-team headed by Marcel Risch has observed at BESSY II how two simultaneous mechanisms are responsible for this. The catalytic activity of the individual catalysis centres decreases in the course of electrolysis, but at the same time the morphology of the catalyst layer also changes. Under favourable conditions, considerably more catalysis centres come into contact with the electrolyte as a result, so that the overall performance of the catalyst increases.

As a rule, most catalyst materials deteriorate during repeated catalytic cycles – they age. But there are also compounds that increase their performance over the course of catalysis. One example is the mineral erythrite, a mineral compound comprising cobalt and arsenic oxides with a molecular formula of (Co3(AsO4)2·8H2O). The mineral stands out because of its purple colour. Erythrite lends itself to accelerating oxygen generation at the anode during electrolytic splitting of water into hydrogen and oxygen.

Samples from Costa Rica

The young investigator group headed by Dr. Marcel Risch at the HZB together with groups from Costa Rica has now analysed these catalysing mineral materials in detail at BESSY II and made an interesting discovery.

Using samples produced by colleagues in Costa Rica consisting of tiny erythrite crystals in powder form, Javier Villalobos, a doctoral student in Risch's group at the HZB, coated the electrodes with this powder. He then examined them before, during, and after hundreds of electrolysis cycles in four different pH-neutral electrolytes, including ordinary soda water (carbonated water).

Loss of original structure

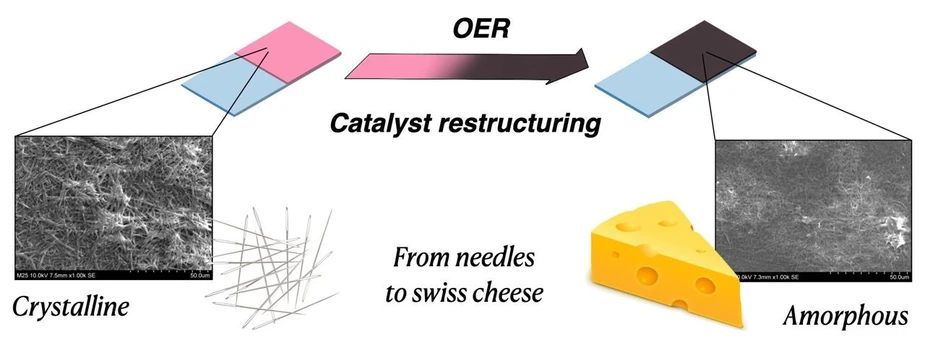

Over time, the surface of each catalytically active layer exhibited clear changes in all the electrolytes. The original crystalline structure was lost, as shown by images from the scanning electron microscope, and more cobalt ions changed their oxidation number due to the applied voltage, which was determined electrochemically. Increased oxygen yield was also demonstrated over time in soda water (carbonated water), though only in that electrolyte. The catalyst clearly improved.

Observations at BESSY II

With analyses at BESSY II, the researchers are now able to explain why this was the case: using X-ray absorption spectroscopy, they scanned the atomic and chemical environment around the cobalt ions. The more active samples lost their original erythrite crystal structure and were transformed into a less ordered structure that can be described as platelets just two atoms thick. The larger these platelets became, the more active the sample was. The data over the course of the catalysis cycles showed that the oxidation number of the cobalt in these platelets increased the most in soda water, from 2.0 to 2.8. Since oxides with an oxidation number of 3 are known to be very good catalysts, this explains the improvement relative to the catalysts that formed in the other electrolytes.

Oxygen yield doubled

In soda water, the oxygen yield per cobalt ion decreased by a factor of 28 over 800 cycles, but at the same time 56 times as many cobalt atoms changed their oxidation number electrochemically. Macroscopically, the electrical current generation and thus the oxygen yield of the electrode doubled.

From needles to swiss cheese

In a nutshell, Risch explains: “Over time, the material becomes like Swiss cheese with many holes and a larger surface area where many more reactions can take place. Even if the individual catalytically active centres become somewhat weaker over time, the larger surface area means that many more potential catalytically active centres come into contact with the electrolyte and increase the yield.”

Risch suggests that such mechanisms can also be found in many other classes of materials consisting of non-toxic compounds, which can be developed into suitable catalysts.

Publication:

Advanced Energy Materials (2021): Requirements for beneficial electrochemical restructuring: A model study on a cobalt oxide in selected electrolytes

Javier Villalobos, Diego González-Flores, Roberto Urcuyo, Mavis L. Montero, Götz Schuck, Paul Beyer, Marcel Risch

DOI: 10.1002/aenm.202101737

Contact:

Helmholtz-Zentrum Berlin für Materialien und Energie

Young Investigator Group Design of the oxygen evolution mechanism

Dr. Marcel Risch

Email: marcel.risch(at)helmholtz-berlin.de

Press Officer:

Dr. Antonia Rötger

Phone: +49 30 8062-43733

Email: antonia.roetger(at)helmholtz-berlin.de

Press release HZB, 9 August 2021