Patented nanostructure for solar cells

Rough optics, smooth surface

Thin-film solar cells made of crystalline silicon are inexpensive and achieve efficiencies of a good 14 percent. However, they could do even better if their shiny surfaces reflected less light. A team led by Prof. Christiane Becker from the Helmholtz-Zentrum Berlin (HZB) has now patented a sophisticated new solution to this problem

"It is not enough simply to bring more light into the cell," says Christiane Becker. Such surface structures can even ultimately reduce the efficiency by impairing the electronic properties of the material.

Rough and smooth

The idea that David Eisenhauer worked out as part of his doctorate in Becker's team sounds quite simple, but it requires a completely new approach: to produce a structure that behaves "optically rough" and scatters the light, but at the same time provides a "smooth" surface on which the silicon layer (the most important layer of the solar cell) can grow with virtually no defects.

Several steps for the SMART surface

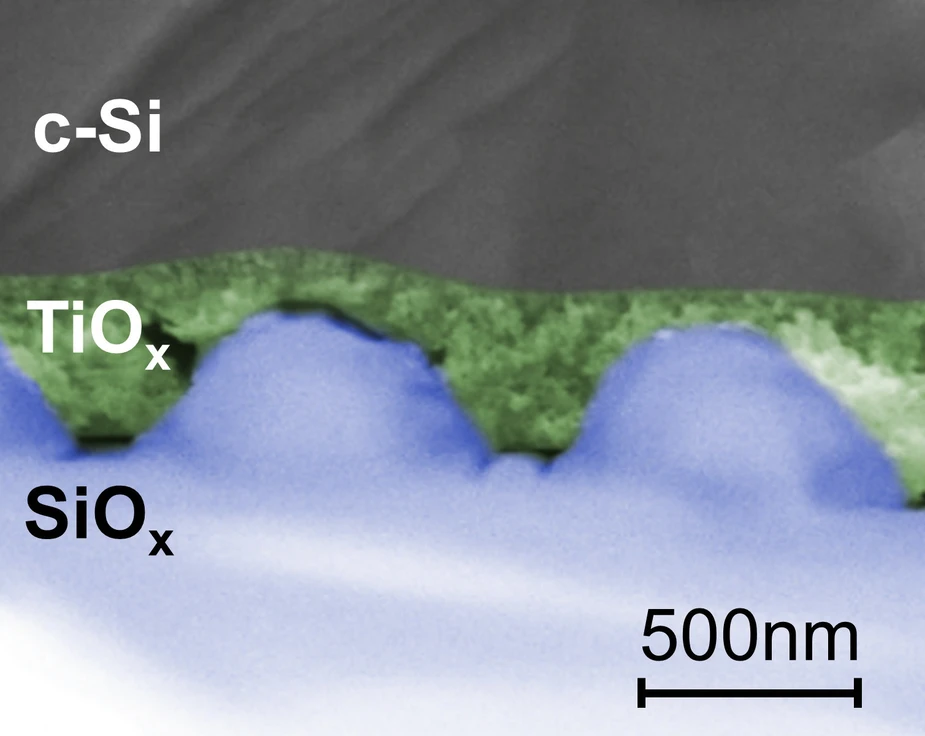

The procedure consists of several steps: first, the researchers imprint an optimised nanostructure onto a still liquid silicon oxide precursor layer that is then cured with UV light and heat. This creates tiny, regularly arranged cylindrical elevations that are ideal for capturing light. However, the absorbing layer of crystalline silicon cannot grow flawlessly on this rough surface, so these structures have an unfavorable effect on the quality of the solar cell. In order to resolve this conflict, a very thin layer of titanium oxide is spin coated on top of the nanostructure in order to produce a relatively smooth surface on which the actual absorber material can be deposited and crystallized.

The coating has the descriptive name "SMART" for smooth anti-reflective three-dimensional texture. It reduces reflections and brings more light into the absorbing layer without impairing its electronic properties. The procedure is now patented.

Christiane Becker heads a Young Investigator Group at the HZB funded by the BMBF under the NanoMatFutur programme. As part of the BerOSE Joint Lab, she works closely with the Zuse Institute to use computer simulations for understanding the effects of nanostructuring on material properties.

Published in Scientific Reports (2017): Smooth anti-reflective three-dimensional textures for liquid phase crystallized silicon thin-film solar cells on glass; David Eisenhauer, Grit Köppel, Klaus Jäger, Duote Chen, Oleksandra Shargaieva, Paul Sonntag, Daniel Amkreutz, Bernd Rech & Christiane Becker

doi: 10.1038/s41598-017-02874-y

Contact:

Dr. Antonia Rötger

Tel: (030) 8062-43733

Fax: (030) 8062 - 42998

E-Mail: antonia.roetger(at)helmholtz-berlin.de