Solar-cell façade at HZB undergoes real-life testing

360 solar modules integrated into the building envelope of the new BESSY testing hall

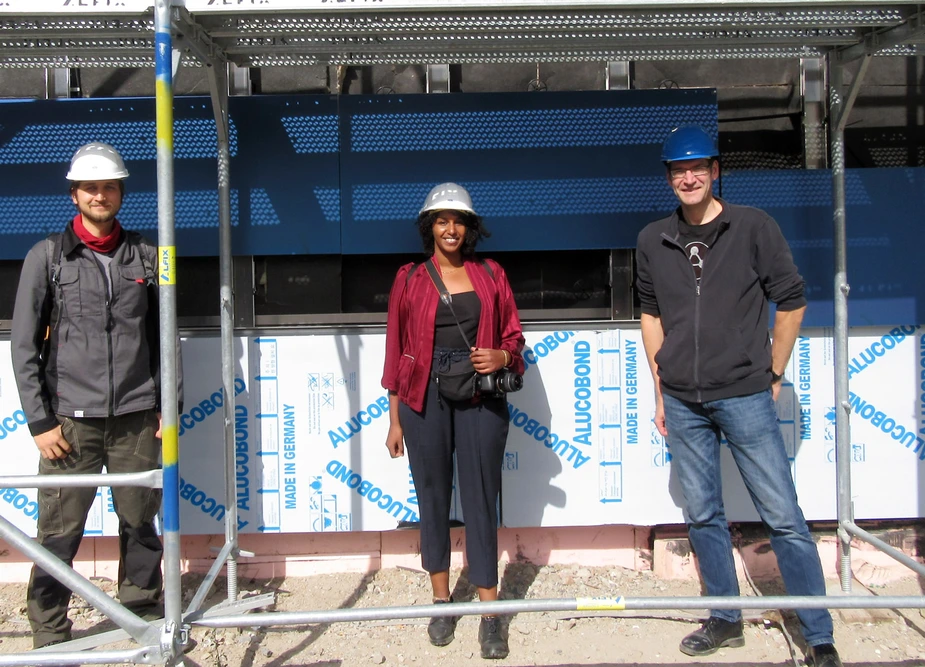

Solar-modules shimmer bright blue on the cladding of a new building at the Helmholtz-Zentrum Berlin (HZB). They are special CIGS thin-film modules custom-developed and produced in Germany for integration into the building’s envelope. The solar cladding not only meets part of the power requirement, but is also a realistic laboratory in and of itself: an HZB team is monitoring the long-term behaviour of the modules under varying environmental conditions and evaluating the data.

The Helmholtz-Zentrum Berlin is one of the leading research institutions in the field of photovoltaics, from pure research to the development of industry-compatible fabrication methods. At HZB, experts at the consulting office for building-integrated photovoltaics (BAIP) offer advanced training courses on innovative cladding solutions for architects or planners. Now for the first time, a newly constructed HZB building has also been equipped with solar modules. This is an extension to the testing hall at BESSY II in Adlershof, where components for accelerator physics are to be developed and tested.

Blue curtain for electricity production

A total of 360 modules have now been mounted on the west, south and even the north side of the outer shell. “It is a curtain façade”, explains Samira Aden, architect at BAIP, who is advising on the project. The modules are hung in front of the cladding using a rail system so that a small air space is created between the module and the thermal insulation. “With the additional sensor technology installed, we intend to find out over the next few years how real weather conditions, fine dust, rain, and pollution affect performance“, she explains.

Sensors for incident radiation and heat

Her colleague Maximilian Riedel, a scientist at PVcomB, is responsible for the sensor technology: “Sensors on each side of the building record the incident radiant power of the sun”, he says. The modules not only generate electricity, they also heat up as a result of the radiation, which in turn can reduce their output. “This is why we measure the temperature on the backside of the modules using 72 thermal sensors. We additionally measure the flow velocity of the air in the gap behind the modules at different points on the façade to see how well the heat is dissipated at various gap widths”, he explains. By comparing the performance of the west, south, and north sides, the experts can make predictions about how the modules behave in direct light or in scattered light.

CIGS-thin film modules

The modules are fabricated by AVANCIS in Torgau near Leipzig. “They are CIGS thin-film modules, and we were able to obtain them in that deep blue colour typical of HZB. The special feature of the modules is the concealed suspension, which allows a frameless design without additional visible hardware at the edge of the module. This allows the modules to be ideally combined with the metal curtain wall of the building. Each module has an output of approximately 135 watts. In total, we have an installed peak power of almost 50 kilowatts”, explains project manager Dirk Mielke of HZB.

Beauty and functionality

“This photovoltaic project is something special”, emphasises Dr. Björn Rau, who heads the BAIP consulting office. For the first time, an entire building with a photovoltaic system integrated into the façade is being operated in a real-life laboratory test. The comprehensive measurement instrumentation facilitates new insights into the actual behaviour of solar modules in a façade during different seasons and weather conditions over a long period of time. “We have deliberately placed great emphasis on the aesthetic integration of the modules into the building envelope in this project. We selected the CIGS material system because of the large amount of expertise we have with it at HZB. Many research groups at HZB work with CIGS thin films, from materials research to the development of building elements”, Rau adds. Large numbers of requests for data and our analyses are already coming in.

Further information:

Helmholtz-Zentrum Berlin für Materialien und Energie

Facility Management, Planning and Construction

Email: FM-B-office(at)helmholtz-berlin.de

Consulting office for building-integrated Photovoltaics (BAIP)

Dr. Björn Rau

Phone: +49 30 8062-18153

Email: bjoern.rau(at)helmholtz-berlin.de

Press release HZB, 24 September 2020