Black-box battery

The Adelhelm Group is advancing alternative battery concepts

Until now, when it comes to storing energy for electric vehicles or for stationary use, there is no way around the lithium-ion battery. However, groups of researchers all over the world are advancing alternative battery concepts. One of these research groups is that of Philipp Adelhelm, which is pursuing new approaches using new materials at the Humboldt University’s Department of Chemistry and the HZB Helmholtz Centre for Materials and Energy in Berlin.

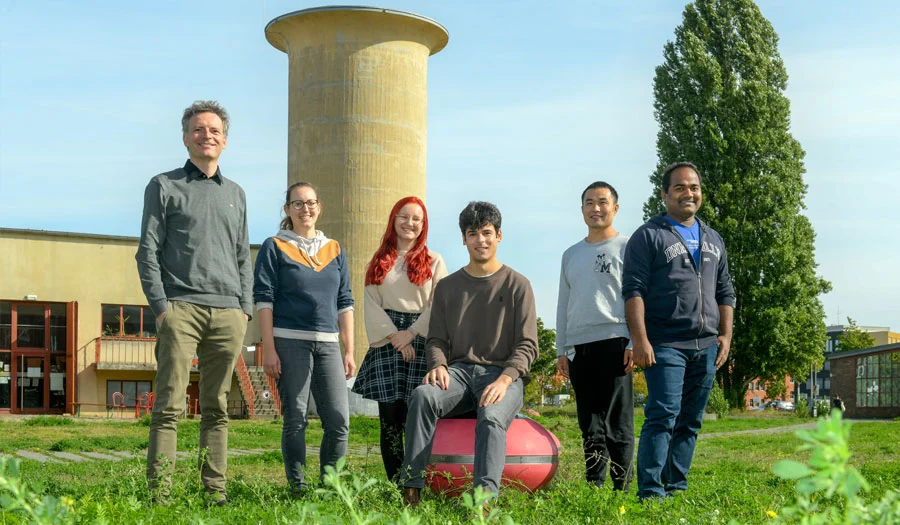

Twenty-five young researchers from ten nations. Every one of them with a story of their own, a cultural background of their own. “You can imagine that our lab work can get quite lively at times,” says Philipp Adelhelm, who is the head of this colourful bunch of researchers, PhD students, and undergrads. Adelhelm’s group is not only diverse in terms of culture but also disciplines: chemistry, physics, materials science, electrochemistry, and analytics. This is a complex social and scientific network that is working every day at the Department of Chemistry of HU and the Helmholtz-Zentrum Berlin für Materialien und Energie (HZB) to shed light into the battery black-box.

A look back: When the era of electromobility was ushered in 15 years ago, great hopes were placed on lithium-ion batteries. At the same time, the novel battery technology also harboured many uncertainties: Manufacturing and process technology for building large-scale batteries were at the very beginning of their development.

The cost of this energy storage technology was not remotely attuned to the price expectations of car manufactures. Moreover, a sufficient and sustainable supply of lithium or other metals like cobalt and nickel was also not in the stars. Last but not least, there were doubts about their longevity, the number of charging cycles, and battery security—especially since the black-box battery did not reveal to them which chemical and physical processes were happening in addition to the desired ion transfer between anode and cathode during charging, discharging but also in its inactive state.

This is where the initial approach of the Berlin-based research group comes into play. They observe the processes of lithium-ion batteries in situ, i.e., while the battery is in operation, which is why it is called Operando Battery Analysis. This research focuses on further optimisation of the lithium-ion technology regarding a longer lifespan and higher energy density while using less materials. Other key aspects of Adelhelm’s team include sodium-ion batteries and other novel concepts in which compressed solids replace the highly flammable liquid electrolytes of today's batteries. This could lead to intrinsic safety—which, however, is still at the basic research level.

Sodium-ion technology, on the other hand, has already progressed. Only recently, one of the industry’s top dogs—the Chinese Contemporary Amperex Technology Co. Limited (CATL)—announced that it would launch mass production of sodium-ion batteries in 2023. “While this was surprising to us, it also made us quite happy because it will boost this whole research field,” says Adelhelm. Until now, sodium-ion batteries do not quite research the energy density of modern lithium-ion technology. But they have surpassed the long-favoured nickel-metal hybride batteries that Toyota famously used for their hybrid engines. “Certain sodium-ion batteries can be charged very quickly, and they are less sensitive to heat as lithium-ion technology,” he says. There are many other points on the list of advantages. Sodium-ion batteries can be produced using the same manufacturing technology as lithium-ion batteries, while replacing copper, the more expensive electrode material, with aluminium. Finally, a steady supply of sodium is unproblematic and would make the use of cobalt and nickel obsolete, two metals that are expensive as well as ecologically and ethically questionable.

It remains to be seen whether the technology will prevail in electromobility or in stationary use despite its lower energy density—which leads either to more weight or lower range. The surprise announcement of CATL has injected some fresh motivation into the already busy lab life of the Adelhelm Group. “We like to do company outings in Berlin and the surrounding areas from time to time to release the tension and have some fun,” says Adelhelm. Since everybody knows each other quite well from their day-to-day work, this often feels like a family outing to him.

Peter Trechow for Adlershof Journal