Fast and precise

Innovative diode lasers and LEDs are tapping into new potential for machine building, medical engineering, and other applications

Since the nineties, laser and LED technology has been inconceivable without gallium nitride (GaN). This chemical substance provides the basis for white LEDs and the blue diode lasers, e.g. in Blu-Ray players. Yet this does not even touch the extent of their true potential: The Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik (FBH) has set itself the target of expanding this range of applications.

The research projects pursued at the FBH include the association project “Advanced UV for Life”, involving 31 partners from industry and science. The object is to develop ultraviolet LEDs and their applications. “Conventional UV lamps based on mercury are unsuitable for many applications,” explained Sven Einfeldt from the FBH Business Unit for GaN Optoelectronics. For example, these conventional laser sources do not allow specific UV wavelength configurations – unlike diodes of gallium and aluminium nitride.

The challenge: “Mixed crystals of this kind are difficult to manufacture,” confided Einfeldt. “There is no substrate that allows the perfect growth of gallium or aluminium nitride crystals.” Yet this perfect growth is essential for the successful use of UV LEDs. Potential uses are manifold: therapy for skin diseases, for instance, the environmental and life sciences, the disinfection of drinking water, or the treatment of lacquers and paints.

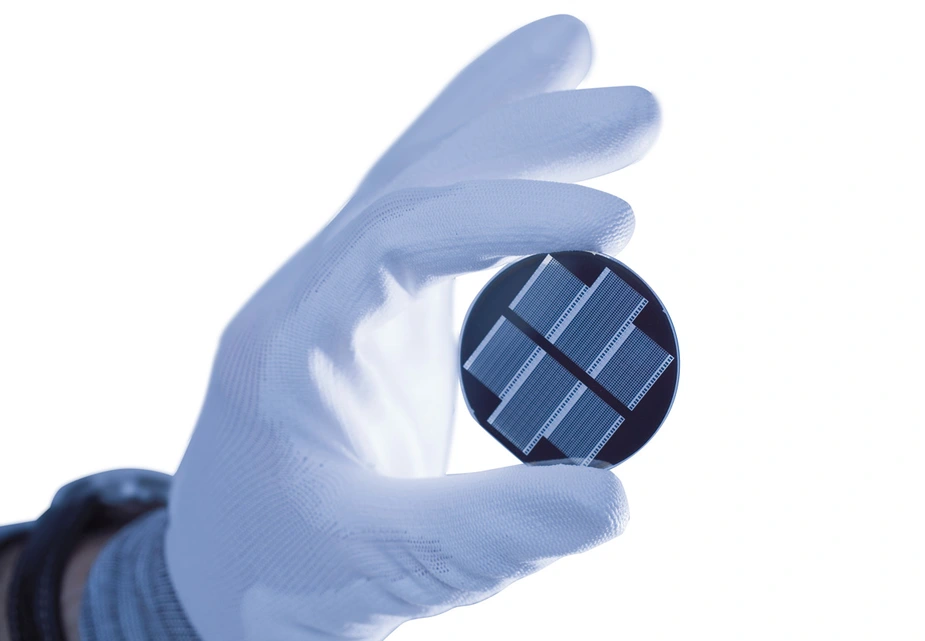

Also the company DirectPhotonics, set up in 2011, has its eye on practical applications. Its specialised field deals with innovative, high performance diode lasers that are ideal for cutting and welding metal and for 3D production.

“You could say we’re selling the optical engine for machine building,” explained founder and Managing Director Wolfgang Gries. “For this purpose, we combine semiconductors in such a way that they exhibit a particularly high beam performance.”

Just recently, DirectPhotonics developed initial products that were tested in an industrial environment. This year should see their launch. The extremely precise and reliable diode lasers, for example, allow innovative designs in the automotive industry and computer production. Gries is convinced: “This business field has a future. What makes this laser technology so appealing is its automation level, its enhanced precision, and hence its essential contribution to the flexibility of industrial production.” In his view, the advantage of Adlershof lies in its basic research.

By Christian Hunziker for Adlershof Special