Light controls repair of materials

Team of researchers led by chemists of the HU develops self-repairing plastic coating

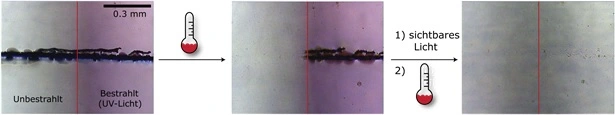

A team of German researchers led by chemists of the Humboldt-Universität zu Berlin has developed a new type of plastic coating, which can heal damages selectively by illumination with light. A heat-induced repair of the material occurs where the damaged area has previously been illuminated with light of a specific color. The promising results of this work have now been published in Nature Communications.

To avoid the environmentally unfriendly as well as expensive replacement of damaged consumer products and constructions, researchers have recently been focusing their efforts on the development of smart materials able to self-repair scratches or cracks. Especially plastic coatings, which are repaired by heat, have yielded promising results in the past. Once subjected to heat, a chemical reaction induces melting and thus enables a homogeneous and complete mending. Upon cooling, the plastic re-establishes its original chemical structure as well as mechanical properties: It hardens and becomes robust again. However, the thermal stress during the healing procedure affects the overall material properties and eventually leads to degradation when applied repeatedly.

To bypass this problem, German researchers from the Humboldt-Universität zu Berlin, the Friedrich-Schiller-University in Jena, the Federal Institute for Materials Research and Testing in Berlin as well as the Helmholtz-Zentrum Geesthacht in Teltow have now developed a smart plastic coating, in which light focusses the thermal healing process to the damaged locations only, without affecting the non-damaged parts.

“We aimed to protect intact parts of coatings from degradation.”, says lead researcher Stefan Hecht and adds: “By employing light as stimulus, we now have a true remote control to switch the ability to self-repair ‘on’ or ‘off’ on demand.” Shining light on damaged areas of the coating enables the self-repairing function. This process can be reversed by changing the color of the employed light yielding the original material – but in the healed state.

This seminal development is an important step to future applications in consumer products where light as a remote control facilitates external control over properties of smart materials. This could include the use as latent resists carried through various processing steps in nanofabrication or 3D printing.

Conditional repair by locally switching the thermal healing capability of dynamic covalent polymers with light

A. Fuhrmann, R. Göstl, R. Wendt, J. Kötteritzsch, M.D. Hager, U.S. Schubert, K. Brademann-Jock, A.F. Thünemann, U. Nöchel, M. Behl und S. Hecht

Nature Communications (2016), published online

DOI: 10.1038/ncomms13623

Contact

Prof. Stefan Hecht, Ph.D.

Humboldt-Universität zu Berlin

Institute for Chemistry & IRIS Adlershof

Tel.: 030 2093-7365

sh(at)chemie.hu-berlin.de