Milled, not stirred

At the Federal Institute for Materials Research and Testing (BAM) new successes for green chemistry are achieved with smart processes

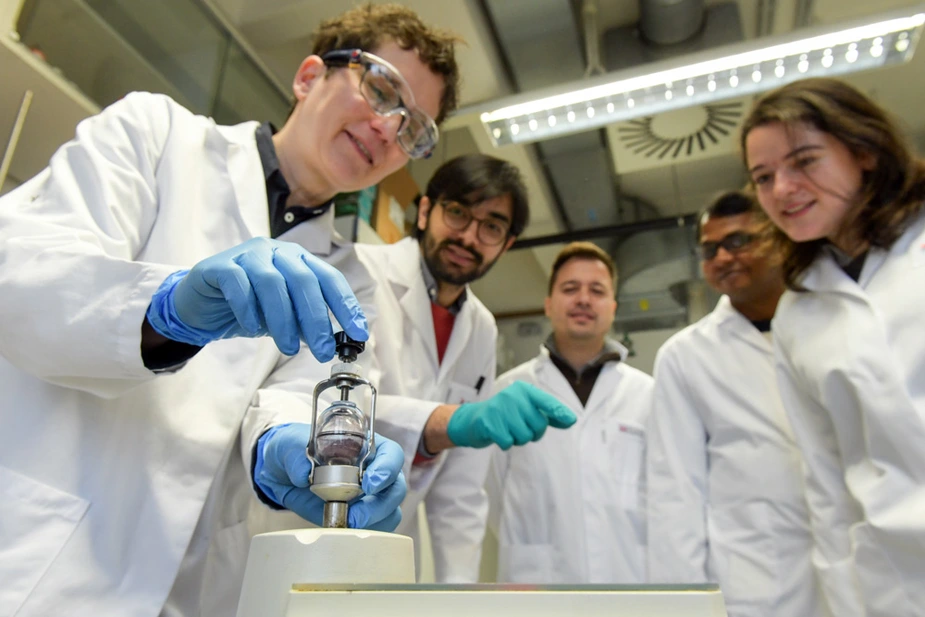

It’s hard not to think of medieval times when someone speaks of clattering mills. However, what Franziska Emmerling and her team practice is high-level chemistry. The head of the Structure Analysis division at the Federal Institute for Materials Research and Testing (BAM) in Adlershof looks at reactions where mechanical actions play a decisive role. This does not require liquid solvents, heating, or other impulses from light or electricity.

This is what happens, for example, when using a ball mill. A receptacle is attached to a moveable disk and equipped with powdery source materials and a few steel balls. The rotation causes the balls to fall into the material, which is pulverised by the resulting mechanical energy. This also triggers chemical reactions until the jar is filled with a powdery final product.

The principle is ancient. There are reports as far back as the pre-Christian fourth century, whereby metallic mercury was made by grinding cinnabar in a mortar made of copper. Today, these types of processes are called ‘mechanochemistry’, a field that is now being systematically researched. Emmerling’s international team of post-docs, PhD students, and experienced colleagues are also dedicated to this endeavour.

Some of the open questions included what happens when the steel balls hit the powder particles. Which intermediate or end chemical products are created by different types of mills? When does the reaction end? ‘The milling procedure and the chemical processes occurred like in a black box,’ says the chemist, who completed her PhD in Freiburg and her habilitation thesis at Humboldt-Universität zu Berlin.

There is hardly a better place to decipher the processes in her milling jar than Adlershof, a neighbourhood that houses top-level research institutes and the electron storage ring Bessy II. X-ray crystallography and Raman spectroscopy enable her to analyse the reaction process with precision but without having to stop the milling process or open the jar.

While these jars are usually made of a lightproof material like steel or other alloys, the ones used by the BAM researchers are custom-made.

Franziska Emmerling places the avocado-sized acrylic glass vessel on the table, adds two steel balls with a 10-millimetre diameter, and starts shaking. The balls click. It looks like a game. However, analysing the processes in a grinding bowl vibrating at 30 hertz can be challenging. Determining the course of reactions from powder data is what fascinated her when she started focusing on this field of chemistry a good ten years ago, says Emmerling. It was worth the effort. She is now able to calculate a three-dimensional structure from the one-dimensional spread pattern provided by BESSY’s measurements.

The BAM team is particularly successful in the manufacturing of pharmaceutical products, including so-called cocrystals. These are crystalline systems that combine an active pharmaceutical ingredient with an additional organic substance. Theophylline, for example, is helpful against respiratory diseases but is hard to absorb by the human body due to its low water solubility. Here, it can help to grind the active ingredient with benzamide using a ball mill. In just a few minutes, the milling creates a cocrystal that is quicker and more soluble than the active ingredient itself. It is due to these solutions and their environmental benefits that mechanochemistry is getting more attention on a global scale. ‘The industry is very interested in what we do,’ says the Palatinate native, who has been doing research at BAM for 16 years.

By Paul Janositz for Adlershof Journal