Solar cells produced from liquid inks were tested under real life conditions in the field

HZB team optimises metal halide perovskites for the slot die coater – a step towards industrial production

Solar cells made from metal halide perovskites achieve high efficiencies and their production from liquid inks requires only a small amount of energy. A team led by Prof. Dr. Eva Unger at Helmholtz-Zentrum Berlin is investigating the production process. At the X-ray source BESSY II, the group has analyzed the optimal composition of precursor inks for the production of high-quality FAPbI3 perovskite thin films by slot-die coating. The solar cells produced with these inks were tested under real life conditions in the field for a year and scaled up to mini-module size.

Metal halide perovskites are considered to be a particularly low-cost and promising class of materials for next-generation solar modules. Perovskite solar cells can be produced with coating processes using liquid inks made from precursor materials and various solvents. After coating, the solvents evaporate and the perovskites crystallise to form a more or less homogeneous layer.

Options for upscaling

Prof. Dr. Eva Unger's team at Helmholtz-Zentrum Berlin has extensive expertise in solution-based processing methods and is investigating options for upscaling. "Perovskite photovoltaics is the best solution-processable PV technology available," says Eva Unger, "but we are only just beginning to understand how the complex interaction of the solvent components affects the quality of the perovskite layers."

Variations of viscosity

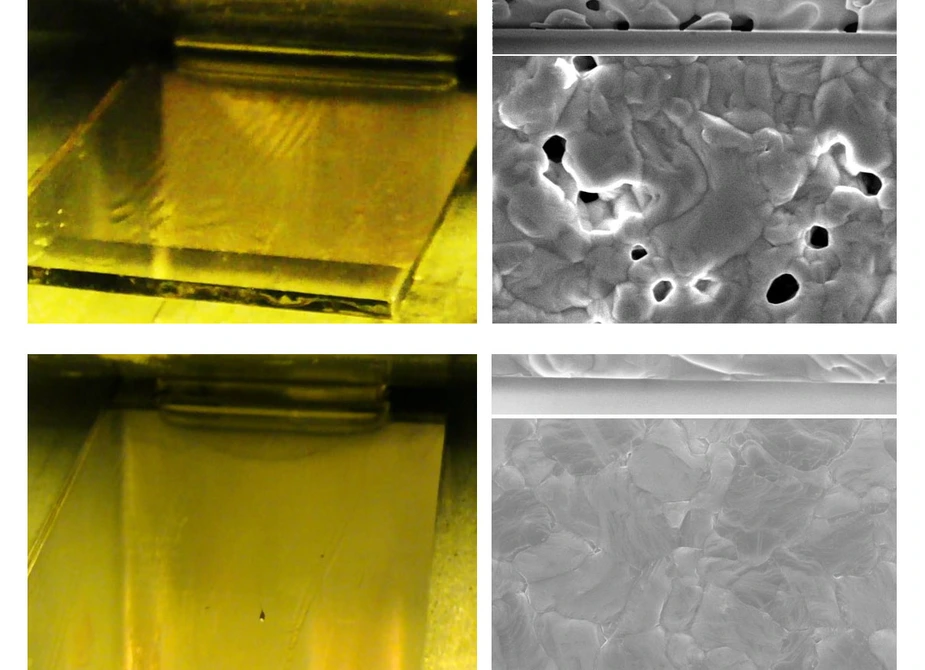

This is because when the halide perovskite layers are coated on large surfaces, unwanted inhomogeneities can occur, for example so-called ribbing structures. "By varying the viscosity of the ink, such effects can be minimised," says Jinzhao Li, who is doing his PhD with Unger. At BESSY II, he has investigated how different solvent combinations affect the crystallisation of the perovskite films. The best p-i-n-FAPbI3 perovskite solar cells thus achieve a certified efficiency of 22.3 % on a laboratory scale. Jinzhao Li also produced mini solar modules (active area of 12.6 cm2) with colleagues from the HySPRINT innovation lab and PVcomB, which achieved efficiencies of around 17 %.

Outdoor test for one year

Dr Carolin Ulbrich's team tested the optimised solar cells at PVcomB’s outdoor test facility for a whole year: In the process, the efficiency remained almost stable in winter and spring, and only dropped in the warmer summer months. "These tests of larger modules under real conditions give us valuable information on degradation mechanisms to then further improve the long-term stability of halide perovskite photovoltaics," says Eva Unger.

Publication:

Advanced Energy Materials (2023): Ink Design Enabling Slot-Die Coated Perovskite Solar Cells with >22% Power Conversion Efficiency, Micro-Modules, and 1 Year of Outdoor Performance Evaluation

Jinzhao Li, Janardan Dagar, Oleksandra Shargaieva, Oliver Maus, Marco Remec, Quiterie Emery, Mark Khenkin, Carolin Ulbrich, Fatima Akhundova, José A. Márquez, Thomas Unold, Markus Fenske, Christof Schultz, Bert Stegemann, Amran Al-Ashouri, Steve Albrecht, Alvaro Tejada Esteves, Lars Korte, Hans Köbler, Antonio Abate, Daniel M. Többens, Ivo Zizak, Emil J. W. List-Kratochvil, Rutger Schlatmann, Eva Unger.

DOI: 10.1002/aenm.202203898

Contact:

Helmholtz-Zentrum Berlin für Materialien und Energie

Department Solution Processing of Hybrid Materials & Devices

Prof. Dr. Eva Unger

Young Investigator Group Leader

Phone +49 30 2093-82550

Email eva.unger(at)helmholtz-berlin.de

Dr. Antonia Rötger

Science communication

Phone +49 30 8062-43733

Email antonia.roetger(at)helmholtz-berlin.de

Press release HZB, 16 March 2023