The asbestos scouts: On the hunt for the hazardous fibres

The analytics company LFM (Labor für Mikroanalytik) examines building materials for hazardous substances in low concentrations

Labor für Mikroanalytik (LFM), an analytics company, was founded in Adlershof just one year ago. The main task of its employees is to trace asbestos and other hazardous mineral fibres. Their services are in high demand. While most classic asbestos products, including plates and insulation material, will soon have vanished due to renovation, there is an increasing amount of low-concentration asbestos being discovered in tiles, glues, roof felt, and floor screeds.

And so, it seems like the hunt for the little, hidden products is taking up steam. Holger Fitzke, the CEO of LFM, had the idea that started everything after meeting his future business partners on the Adlershof campus.

‘Hazardous materials in low concentration in building materials have long been ignored,’ he says, ‘take filler between plasterboards, for example, or PVC floor tiles, or roof felt.’ These substances are toxic as well as carcinogenic. A large public housing provider from Berlin is now one of the customers of Fitzke and his team. Whenever somebody moves out of a flat, they move in and run the tests – and, if required, the flat is renovated afterwards. When no traces of asbestos fibres are left in the room air, the next tenant can move in.

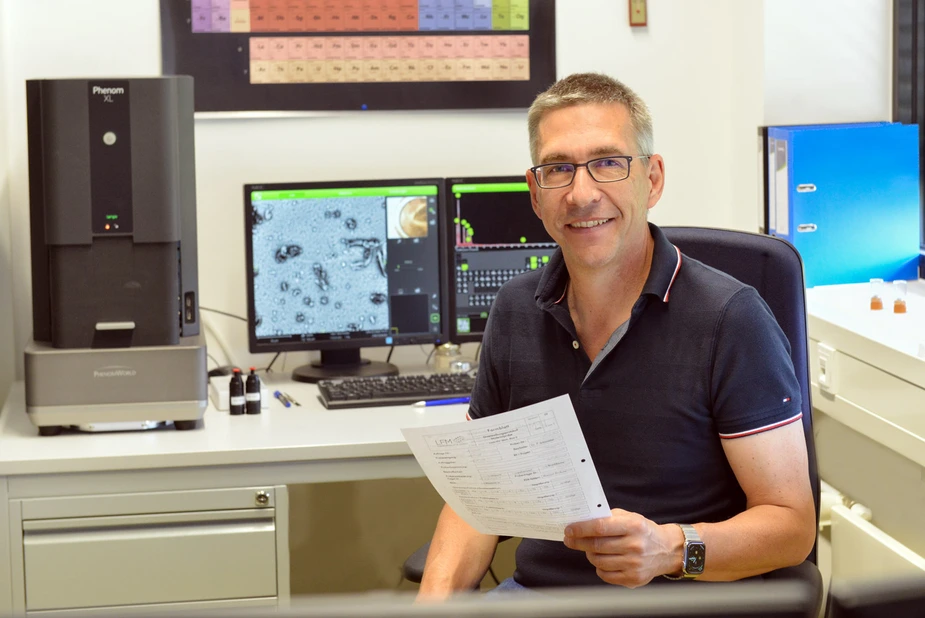

Fitzke studied materials technology in Merseburg and works for the Adlershof-based Büro für Umweltplanung, a service and consulting company for construction and environmental technology. He has a scanning electron microscope (SEM) in his physical laboratory, which his staff use to detect asbestos concentration of below one percent. The majority of old roof felt still contains these traces. The sample is put into a vacuum inside the REM and targeted by electron beams. Even fibres that are buried deep inside the sample can thus be magnified by up to 100,000 times and promptly measured and analysed by special software on a computer. Carcinogenic mineral fibres are analysed in the same way.

‘Buildings are my key area of expertise,’ says Holger Fitzke. ‘With disputes in court, disposal, planning of refurbishments, or measurements of potentially contaminated indoor air, our analyses tend to be the clincher.’ The LFM’s team is currently active all over Berlin in schools and other public buildings. Most of the asbestos and mineral fibres here is hidden in acoustic ceilings. Fitzke and his staff are often called to help with emergency situations. Worried parents will refuse to send their children to school, and teachers, too, stay home for weeks and will not return before a final report has been issued. These are sent to customers electronically. ‘In February we finally became a full accredited laboratory,’ says Fitzke, ‘this is important to facilitate comparability. Uncertainty can result in health risks, high costs, or even life-threatening situations.’

The CEO praises the outstanding working conditions on campus. Vents, special cupboards, or electronics, everything had been provided for. It was the perfect place for a physical laboratory. The LFM has since become a key company for the analysis of old and new (hazardous) mineral fibres. Based on technology and experience, the scientists are capable of distinguishing carcinogenic from newer, more harmless mineral wool.

In addition to buildings, road surfaces, and many other things that are subject to testing, LFM now became a partner of ‘Zentrales Innovationsprogramm Mittelstand’, a government-funded research project for innovation for small and medium-sized enterprises. Holger Fitzke met researchers of the Institut für angewandte Photonik e. V. (IAP), a research institute, at Adlershof’s annual meet-up. They had been developing a WDSX detector aimed at making analytics faster and more accurate. LFM contributes comparative probes and data to the project. In cooperation with RWTH Aachen and the company Nano Optics Berlin, they then develop calculations for user data. One of the things the analysts hope to achieve is to improve the analysis of glass. Glass contains boron, which is so light that it is hard to analyse using an REM.

No matter which building materials are used, health issues are clearly becoming more important. Private houseowners are starting to submit samples to LFM. Historical preservationists, too, send in colours. This is not to check their hazardousness but their make-up. A scanning electron microscope can tell exactly whether the colour was made using copper or other materials.

By Katrin Reisinger for Adlershof Journal