The Pocket-Sized Laboratory

The start-up diamond inventics finds legionella at record speed

Precise, fast, energy and water-saving and about the size of a credit card. An innovative chip system can detect pathogenic microorganisms in water samples on the ground. The test was developed by diamond inventics, a start-up that recently moved into the Center for Biotechnology and Environment in Adlershof.

Commonly used methods require the sample to be moved from the place of sampling to a laboratory and to multiply possible bacteria in a culture solution. Reliable proof took days or even weeks. “Using our quick test, it takes 30 minutes and we know whether we have legionella, salmonella, or the intestinal germ Escherichia coli,” biotechnologist Robert Niedl tells us. Every pathogen with an antibody is traceable. For now, the founders of diamond rely on having these substances delivered, but everything else is do-it-yourself, including the tiny filters made of high-purity cellulose, which are permeated by tiny canals and coated with special chemicals. They are the heart of the mini-lab. The filter structure and the measurement chip are also produced in the company’s lab using a 3D printer.

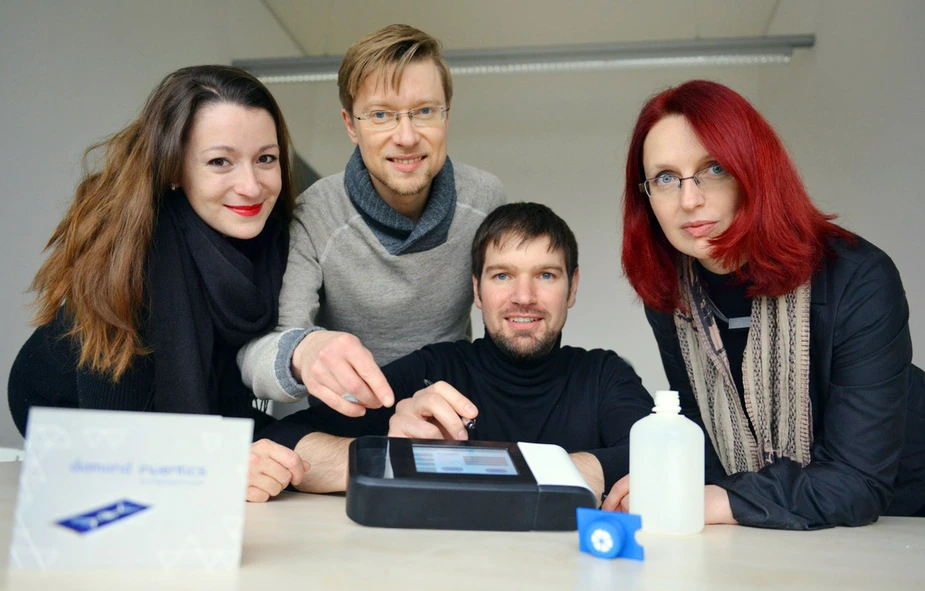

In his dissertation at the University of Potsdam, Niedl dealt with microfluidics, a method of examining and utilising the behaviour of small amounts of liquid in a tiny space. In the three following years, he worked on realising his business idea of the “credit-card-sized lab” with three other partners in crime: industrial designer Nicole von Lipinski, physicist Alexander Anielski, who developed the measurement technology, and business manager Katja Richter, who is responsible for business development.

Niedl and Richter met at a speed dating event for company founders and business experts at the University in Potsdam, where she was quickly convinced by the business idea. Niedl also received “invaluable support”, as he puts it, from the team of Professor Carsten Beta (Institute for Biological Physics, University of Potsdam). He received a one-year EXIST founding grant in June 2015. Business is going well. Two more employees will join the team soon and more are sure to follow.

The quick test is especially interesting for large companies. The process water used in industrial manufacturing, which is typically heated up to 50 degrees Celsius, is not hot enough to kill legionella, say. While testing took up to two weeks in the past, now all it takes is to wait a few minutes for the colour of the filter paper to indicate whether there is any danger of pathogens. These paper tests don’t yet supply quantitative results, but a reliable classification into “dangerous” or “safe” While the system is not yet designed for private use, its founders can well imagine developing the product in that direction. They already have plans to make the system controllable by smartphone. Richter predicts: “Who knows, maybe someday you will buy our quick test at a pharmacy or a home improvement store.”

By Paul Janositz for Adlershof Journal