3D tomographic imagery reveals how lithium batteries age

Researchers have documented the degradation process of lithium electrodes in detail for the first time

Lithium batteries lose amp-hour capacity over time. Microstructures can form on the electrodes with each new charge cycle, which further reduces battery capacity. Now an HZB team together with battery researchers from Forschungszentrum Jülich, the University of Munster, and partners in China have documented the degradation process of lithium electrodes in detail for the first time. They achieved this with the aid of a 3D tomography process using synchrotron radiation at BESSY II (HZB) as well at the Helmholtz-Zentrum Geesthacht (HZG). Their results have been published open access in the scientific journal “Materials Today”.

Whether electric mobility, robotics, or IT – lithium batteries are simply used everywhere. Despite decades of improvements, it has not yet been possible to prevent such batteries from “ageing”. Amp-hour capacity is lost with every charge cycle. The processes that lead to this are roughly understood. Now an international team headed by HZB researcher Dr. Ingo Manke has been able to observe with microscopic precision exactly what happens inside the battery at the interfaces between the electrodes during migration of the lithium ions.

3D insights into lithium cells

Manke is an expert in 3D synchrotron tomography, a method that utilises particularly intense X-rays. 3D images can be created of the interior of samples using this non-destructive imaging method with particularly high precision that is available on the BAM beamline at BESSY II. His team investigated a number of different lithium cells during charging and discharging under different cycle conditions. All cells studied had one side of the electrode made of pure lithium, while the other side was constructed of a selection of different electrode materials. Part of the investigation also took place at the Helmholtz-Zentrum Geesthacht.

Formation of microstructures

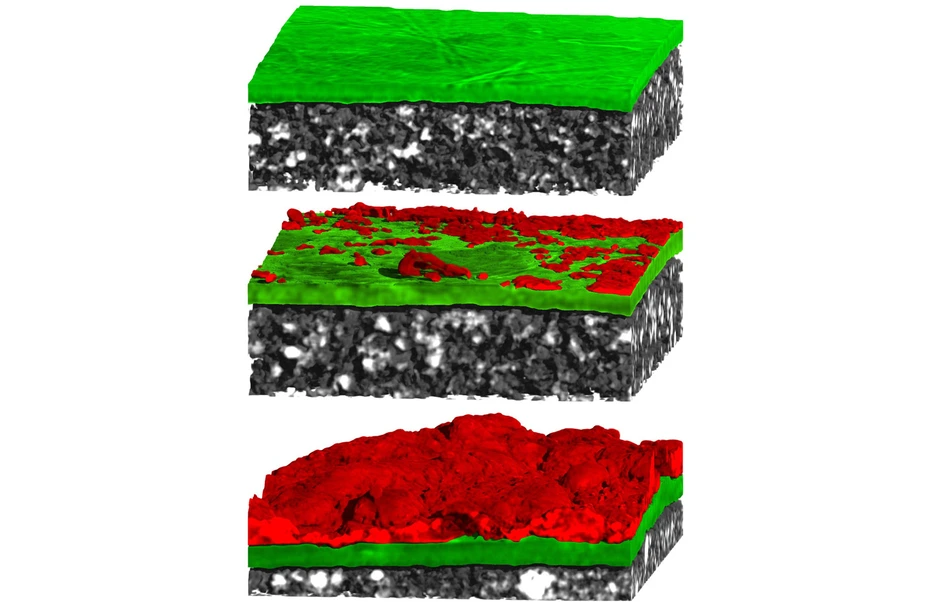

The tomographic imagery shows how a layer forms between the separator layer and the lithium electrode characterised by microscopic features after only a few charge/discharge cycles. The microscopic features of this layer consist of reaction compounds that form in the electrolyte and can take different forms – from a rather disordered slurry, to moss-like structures, to needle-shaped dendrites that can even cause dangerous short circuits in the battery.

“This gives us for the first time a complete picture of the degradation mechanism in lithium electrodes”, says Manke. It is not only of interest for fundamental understanding of the aging processes in batteries, but also provides valuable directions in the design of more durable batteries.

Publication:

Materials Today (2018): “Advancing knowledge of electrochemically generated lithium microstructure and performance decay of lithium ion battery by synchrotron X-ray tomography”

Fu Sun, Xin He, Xiaoyu Jiang, Markus Osenberg, Jie Li, Dong Zhou, Kang Dong, André Hilger, Xiaoming Zhu, Rui Gao, Xiangfeng Liu, Kai Huang, De Ning, Henning Markötter, Li Zhang, Fabian Wilde, Yuliang Cao, Martin Winter, Ingo Manke.

DOI: 10.1016/j.mattod.2018.11.003

Further information

Helmholtz-Zentrum Berlin für Materialien und Energie

Institute Applied Materials

Dr. Ingo Manke

Head of Imaging Group

Tel. +49 30 8062-42682

Email: manke(at)helmholtz-berlin.de

Press Officer:

Dr. Antonia Rötger

Tel.: +49 30 8062-43733 / -14759

Email: antonia.roetger(at)helmholtz-berlin.de