Ageing processes of lithium button cells made visible

For the first time, scientists were able to observe how the composition of lithium-ion batteries changes during charge cycles

Lithium button cells with electrodes made of nickel-manganese-cobalt oxides (NMC) are very powerful. Unfortunately, their capacity decreases over time. Now, for the first time, a team has used a non-destructive method to observe how the elemental composition of the individual layers in a button cell changes during charging cycles. The study, now published in the journal Small, involved teams from the Physikalisch-Technische Bundesanstalt (PTB), the University of Münster, researchers from the SyncLab research group at HZB and the BLiX laboratory at the Technical University of Berlin. Measurements were carried out in the BLiX laboratory and at the BESSY II synchrotron radiation source.

Lithium-ion batteries have become increasingly better. The combination of layered nickel-manganese-cobalt oxides (NMC) with a graphite electrode (anode) has been well established as the cathode material in button cells and has been continuously improved. However, even the best batteries do not last forever; they 'age' and lose capacity over time.

‘A lot happens at the interfaces between the anode, separator and cathode while a battery is charging or discharging,’ explains Ioanna Mantouvalou, physicist at HZB and first author of the study. Typically, these changes are only studied after the battery has been disassembled, i.e. ex situ and at a specific point in the cycling process. But there is now another way: in situ and operando experiments allow to look inside the battery while the processes are taking place, using X-ray fluorescence (XRF) and X-ray absorption spectroscopy (XAS) in a so-called confocal geometry. This geometry permits 3D scanning of a sample with depth resolutions down to 10 µm. Such experimental setups are already possible at the synchrotron radiation source BESSY II. However, the measurement time at BESSY II is limited, so batteries cannot be studied over their entire lifetime.

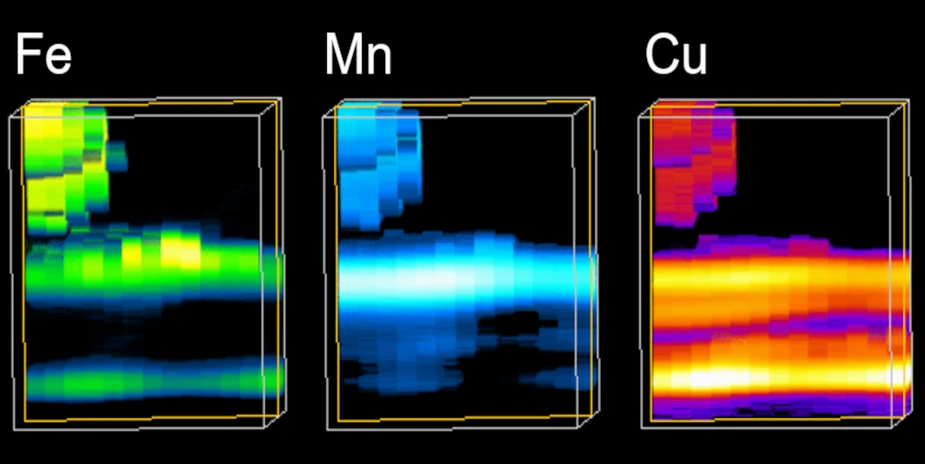

Ioanna Mantouvalou therefore uses a confocal micro X-ray fluorescence spectrometer at BLiX, which can analyse samples fully automatically over long periods of time. ‘The confocal setup allows us to distinguish the individual layers from the NMC cathode to the back contact and to study their elemental composition. This gives us spatially resolved insights into the operation without changing the layer stack. Non-destructive! Quantitative, under operating conditions, i.e. operando,’ says Mantouvalou.

The researchers analysed a lithium button cell on the BLiX instrument for several weeks and over 10,000 charge cycles, providing data on the degradation of the NMC electrode over time. In addition, the sample was examined at the new microfocus beamline (MiFO) in the PTB laboratory at BESSY II.

The study shows that during the first three weeks, manganese in particular dissolves from the NMC cathode and migrates to the carbon anode. This process takes about 200 cycles. After that, the compound increasingly dissolves in the intermediate layers, which stops further reactions and processes. ‘We urgently need such quantitative results to further improve batteries,’ says Mantouvalou. The device in the BLiX laboratory can also be used for experiments on other materials.

Publication:

Small (2025): Operando measurement of transition metal deposition in a NMC Li-ion battery using laboratory confocal micro-X-ray fluorescence spectroscopy

Ioanna Mantouvalou, Lena Mathies, Katja Frenzel, Yannick Wagener, Leona Johanna Bauer, Daniel Grötzsch, Matthias Müller, Birgit Kanngießer, Martin Winter, Sascha Nowak, Adrian Jonas, Burkhard Beckhoff

DOI: 10.1002/smll.202502460

Contact:

Dr. Ioanna Mantouvalou

Helmholtz-Zentrum Berlin für Materialien und Energie

Joint Research Group - SyncLab – Combined X-ray methods at BLiX and BESSY II

ioanna.mantouvalou(at)helmholtz-berlin.de

Dr. Antonia Rötger

Helmholtz-Zentrum Berlin für Materialien und Energie

Press Officer

+49 30 8062-43733

antonia.roetger(at)helmholtz-berlin.de

Press release HZB, 29 April 2025