Green hydrogen from direct seawater electrolysis

International experts compare different approaches and warn against hype

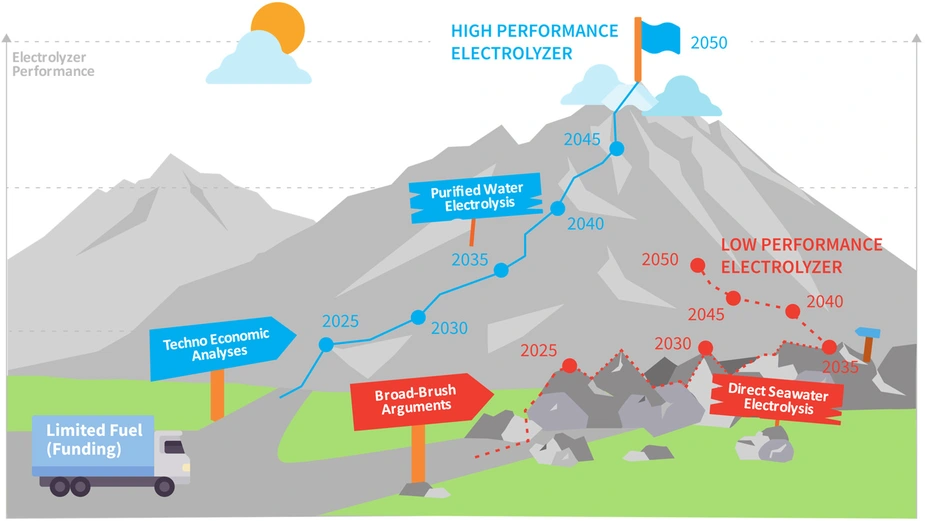

At first glance, the plan sounds compelling: invent and develop future electrolysers capable of producing hydrogen directly from unpurified seawater. But a closer look reveals that such direct seawater electrolysers would require years of high-end research. And what is more: DSE electrolyzers are not even necessary - a simple desalination process is sufficient to prepare seawater for conventional electrolyzers. In a commentary in Joule, international experts compare the costs and benefits of the different approaches and come to a clear recommendation.

Fresh water is a limited resource; more than 96% of the world's water is found in the oceans. If seawater could be fed directly into a future electrolyser to produce green hydrogen using renewable energy from the wind or sun, it sounds like a very good solution. Hundreds of millions of dollars in research fundingare spend for this idea and, in 2023 alone, there have been more than 500 publications (this number is growing exponentially) on direct seawater electrolysis.

No need for new development

However, a techno-economic analysis shows that this argument collapses as soon as the costs and benefits are analysed in more detail. "There is no convincing reason to develop DSE technology because there are already efficient solutions for using seawater to produce hydrogen," says Dr Jan Niklas Hausmann, electrolysis researcher at HZB and lead author of the Joule commentary. International experts from various disciplines from renowned research institutions such as Yale University, universities in Canada, Germany and HZB contributed to the commentary.

Proven methods work

It is already possible to use seawater to produce hydrogen. Proven processes such as reverse osmosis can be used to purify seawater for "normal", commercially available electrolysers. From a thermodynamic point of view, the purification of seawater needs only 0.03% of the energy required for its electrolysis. This is also reflected in the current cost: purifying seawater to produce one kilogram of hydrogen costs less than two cents. However, one kilogram of hydrogen costs 13.85 euros at German filling stations.

Investing money wisely

The development of new types of electrolysers that can operate steadily in seawater would only save this cheap purification step. In contrast, the development of DSE electrolysers is extremely challenging and it is highly questionable whether they will ever be able to match the efficiency and long-term stability of today's electrolysers. Experts see major challenges here: Seawater contains a wide variety of organic and inorganic substances that can cause corrosion and fouling, affecting all parts of the electrolyser. DSE is currently being advertised as a real-world solution for hydrogen production - A promise that cannot be kept and could swallow up a lot of taxpayers' money, the researchers warn.

"We can compare this with the direct use of crude oil to run cars," explains Jan Niklas Hausmann: "It is possible to develop such cars, but they would just not be as efficient and long-lasting as ones running on purified petrol. This is despite the fact that the cost of purifying crude oil (via refinery) is up to 16% of the final price of the fuel, which is significantly higher than the relative cost of purifying seawater for electrolysis (<1%)."

Getting electrolysis research on track to contribute to decarbonisation

"Academic research does not necessarily have to lead to immediate solutions. However, if DSE is presented as a quick fix and is pushed or hyped to the detriment of other more promising approaches, it will tie up resources that will be lacking elsewhere for the development of key decarbonisation technologies," explains Dr Prashanth Menezes, an expert on catalysts at HZB.

"If we want to achieve net zero carbon emissions by 2050, funding must be directed to developments that can quickly contribute to this," says Menezes.

Key points of the techno-economic analysis:

- Commercially already available water purification such as reverse osmosis treats seawater to make it suitable for "normal" electrolysers. The relative costs of this are very low.

- Direct seawater electrolysis poses major challenges for the electrolysers to be developed:

- Biofouling processes

- Corrosion

- Short lifetime and smaller flexibility of electrolysers

Conclusion: The enormous sums of money required for the development of DSE would be better invested in the further optimisation of electrolysers that use highly purified water instead. This is because the water purification process hardly incurs any costs.

Article: DSE for hydrogen production – a solution looking for a problem?

Note: Experts from various disciplines contributed to this commentary: Prof Elimelech and Prof Winter are experts in water purification technologies and authors of a recent report on the use of various impure water sources for hydrogen production, Prof Khan and Prof Kibria are experts in renewable energy storage technologies and their techno-economic analysis and authors of a recent report on the techno-economic aspects of DSE. Dr Sontheimer is an expert in energy technologies and the interaction between science, industry and policy stakeholders; Dr Hausmann and Dr Menezes are experts in materials science, catalysis and water splitting and have recently published a techno-economic analysis of DSE.

Publication:

Joule (2024), Commentary: Hyping Direct Seawater Electrolysis Hinders Electrolyzer Development

J. Niklas Hausmann, Lea R. Winter, M.A. Khan, Menachem Elimelech, Md Golam Kibria, Tobias Sontheimer, and Prashanth W. Menezes

DOI: 10.1016/j.joule.2024.07.00

Contact:

Helmholtz-Zentrum Berlin für Materialien und Energie

Dr. Prashanth Menezes

Email

Jan Niklas Hausmann

+49 30 8062-12957

Email

Dr. Antonia Rötger

Press Officer

+49 30 8062-43733

Email

Press release HZB, 29 July 2024